Infrared Optical Material

The main difference between an infrared optical system and a visible light optical system is only limited types of material can be effectively applied in the MWIR and LWIR bands. Table 2-1 lists several commonly used infrared optical materials and their important characteristics.

2.2.1 Characteristics of Infrared Optical Materials

Infrared optics share some of the following characteristics [see footnotes i, ii, iii]:

(1) infrared materials are not only of limited variety but the price is generally high (usually in the thousands to several million yuan per kilogram).

(2) the material temperature coefficient (dn/dt) can be large, potentially leading to large focal length changes with temperature drift. If there is expected to be a wide working temperature range, you must choose the infrared optical material properly or take the necessary measures to compensate for the temperature fluctuations.

(3) some optical materials are fragile and have poor chemical stability, so that after processing and installation difficulties, the number of actual finished products can be low.

(4) many optically opaque materials show different colors according to both the nature of the materials and the particular infrared band being imaged.

(5) some infrared materials can also heat up, leading to the formation of stray light.

Table 2-1 Common Characteristics of Infrared Optical Materials

|

Material Science |

Refractive index (4 m) |

Refractive index (10 m) |

Dn/dt/ C |

|

Germanium |

4.0243 |

4.0032 |

0.000396 |

|

Silicon |

3.4255 |

3.4179 |

0.00015 |

|

Zinc sulfide (CVD) |

2.252 |

2.2005 |

0.0000433 |

|

Zinc selenide (CVD) |

2.4331 |

2.4065 |

0.00006 |

|

AMTIR I |

2.5141 |

2.4976 |

0.000072 |

|

Magnesium fluoride |

1.3526 |

+ |

0.00002 |

|

Sapphire |

1.6753 |

+ |

0.00001 |

|

Three arsenic sulfide |

2.4112 |

2.3816 |

* |

|

Calcium fluoride |

1.4097 |

+ |

0.000011 |

|

Barium fluoride |

1.458 |

* |

-0.000016 |

|

|

+ |

2.6038 |

0.000091 |

|

|

2.6058 |

2.5858 |

0.000058 |

Notes: "+" not complete transmission; * the index drops sharply

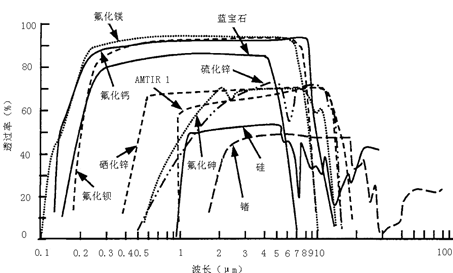

Figure 2.1 Infrared Material Spectral Transmittance

Figure 2.1 is a commonly used infrared transmittance chart including surface losses. Anti-reflective film coatings in the application process can help achieve very high transmission rates (95%-98%). A piece of chalcogenide glass 1mm thick (not shown above) will have an average transmittance of more than 65% between 8-11um, with a fluctuation of less than 3%, and loss of less than 2.4%/cm.

Figure 2.2 Commonly Used Infrared Material (Glass Map)

Common refractive infrared material of glass is shown in Figure 2.2. The vertical axis represents the index of refraction, the abscissa represents the Abbe constant![]() .

.

2.2.2 Commonly Used Infrared Optical Materials

Germanium is one of the most commonly used infrared materials, as it can be used for both long wave and medium wave infrared bands. When used in the LWIR band, there is a similarity to the visible light band when designed as an achromatic lens with crown components; in the MWIR band, which is also similar to the visible light band when designed with an achromatic lens using flint or negative elements. This is the main reason for double color infrared effects caused by color dispersion in the materials. The refractive index and the refractive germanium material rate temperature coefficient are two important parameters to consider. First, the germanium refractive index is slightly larger than 4, which helps to reduce aberration and is consequently favorable to design. However, the Ge temperature coefficient is high at0.000396/Deg C. Since this value is so large, the temperature change process may produce large focal shifts, and the system must use thermal compensation of some kind in the design. So there are advantages and disadvantages with this kind of material. Polycrystalline germanium somewhat solves the problem of non-uniform larger refractive index and an optical designer can choose a single germanium crystal. Germanium can be used with diamond turning processing, but due to its brittleness, it is very susceptible to damage, and great care is necessary in alignment and coating processes. Because of the applications of germanium elements is very wide, its many advantages frequently overweigh the material processing problems inherent in its use.

Silicon and germanium are somewhat similar crystal materials. Silicon material has strong absorption in the 9um to 12um band, so it is mainly used for MWIR, and cannot be used for LWIR. Silicon germanium (refractive index slightly lower than 3.4255), has advantages for aberration control, and has low dispersion. Silicon processing can also be used with the diamond turning method, but the difficulty is large, lossy tool. Silicon though can be readily polished.

Zinc selenide and zinc sulfide also belongs to the category of commonly used infrared optical materials. They can be made by the chemical vapor deposition (CVD) method or by hot pressing. ZnSe and ZnS are relatively expensive, and are mainly suitable for the optical systems that do not have high absorption coefficient requirements.

Calcium fluoride is another material that can be used to make infrared optical prisms, lenses, large aperture lenses, windows and other optical elements. It has a favorable aprochromatic effect, but the price and the cost of processing can be very expensive. In 2002, the largest diameter of calcium fluoride produced was 170mm. Larger sizes are available now, but the price is too expensive. Physical parameters of calcium fluoride glass are shown in Table 2-2.

Table 2-2 Characteristic Parameters of Calcium Fluoride Glass

|

Chemical formula |

CaF2 |

|

Crystal class |

|

|

The lattice constant of (); |

5.46 |

|

The density of (g/cm3) 293K; |

3.18 |

|

Molecular weight |

78.08 |

|

The dielectric constant of (105 Hz) |

6.76 |

|

The melting point of (K); |

1630 |

|

Heat transfer coefficient (.K; W/m 273 K) |

10 |

|

The coefficient of thermal expansion (1/K) 300 K |

18.9 * 10 -6 |

|

Specific heat ( cal/g . K 273 K) |

0.204 |

|

The Debye temperature (K) |

510 |

|

Young's modulus (GPa) |

75.79 |

|

Modulus of rupture (GPa) |

0.0365 |

|

Shear modulus (GPa) |

33.76 |

|

The bulk modulus (GPa) |

83.03 |

|

Poisson's ratio |

0.28 |

|

Knoop hardness ( Kg/mm2) |

178 [100], 160 [110] |

Magnesium fluoride and sapphire are only used for the MWIR spectrum. Because magnesium fluoride has a low refractive index, it usually does not require an anti-reflection film. The price is quite expensive. Sapphire is very hard, but its thermal radiation at high temperature is very low.

The following relationship exists between reflectivity and refractive index of medium:

Infrared material usually has a high refractive index, so the general reflectivity is high. This requires surface coating with anti-reflection film. Because some crystal infrared materials are hygroscopic, there is increased difficulty of optical processing in the workshop. Some materials need coating to prevent moisture damage, for example, and may need to be fabricated in a dry nitrogen environment.